Welcome!

Versaform Corporation is recognized as a world leader in forming, with capabilities involving the Stretch Form, Draw Form, Brake Form and Hydro Forming processes, 5-Axis CNC Routing, as well as Bench Top Assemblies, Sheet Metal Fabrication, Welding and CMM Inspection.

The very latest materials technology and manufacturing systems are employed to produce complex structural components using aluminum, titanium and stainless steel alloys for application within the Aerospace, Military, Architectural and Commercial arenas.

A skilled employment force using, the most advanced equipment available, perform the forming processes with the highest level of precision that meets and often exceeds the Customer specification requirements.

Established internal systems are employed, meeting the requirements of internationally recognized AS9000 and ISO9002 standards.

We encourage you to browse this web site and discover how Versaform Corporation’s commitment to making a quality product, in a timely Manner, at a competitive price may assist in making your next project a complete, profitable success.

Capabilities

Possessing one of the largest inventories of Stretch Forming, Fabrication and Processing equipment in North America, Versaform Corporation’s capability is virtually unlimited with regards to the variety and scope of products and services offered. We specialize in stretch forming extrusion and sheet metal shapes utilizing the process where the metal is stretched around a forming block configured to the customer’s design, tolerances and specifications thereby duplicating the customer’s desired shape or contour.

Versaform Corporation has capabilities to contour any skin, including compound and reverse contours or extrusion configuration. Formed shapes can be contoured from rectangular, round or square tubing, brake form sheet metal shapes such as angles and channels, extrusions, pressure plates, dome caps, ellipses and compound radii. Materials of various descriptions are used to form these shapes including but not limited to aluminum, stainless steel, copper, brass, muntz and carbon steel.

Versaform Corporation also offers secondary forming and manufacturing capabilities such as Ring Roll forming, Compression forming, Brake forming and Stretch Draw forming. These processes combined with our internal Heat Treating capabilities as well as various types of Hardness Testing expands our capabilities even further.

Versaform Corporation competes for business emphasizing the “Big Three” requirements, Quality, Delivery and Price. These requirements combined with the implementation of strong internal procedures, along with an emphasis on Aerospace structures and components coupled with the necessary equipment available to our experienced personnel, allows Versaform Corporation to be a successful and reliable business partner to our customer.

Company Information

Versaform Corporation is a full service, metal forming shop utilizing a quarter century of experience in advanced forming processes to manufacture a wide variety of Aerospace, Military and Commercial structural components. While placing a strong emphasis on Aerospace manufacturing, Versaform Corporation easily services and supports the needs of architectural, commercial glazing, solarium and retail manufacturers throughout the United States, Canada and overseas.

We are experts in:

|

|

|

Our expansive equipment inventory, coupled with our experienced personnel, allows for Versaform Corporation to offer the highest quality product and service unmatched by our competitors. With our expertise and proficiency in forming aluminum, steel, stainless steel, brass, copper, bronze, muntz and other various exotic materials and using our abilities to provide complete design and fabrication services, we have formed thousand of components for companies worldwide.

Certifications

Versaform Corporation employs a Quality System Certified and Registered to the International Standard ISO9002:1994 and Certified to the Domestic Standard AS9000:1998. Our Calibration Systems are compliant to the International Standard ISO10012-1:1993 and to the Domestic Standard ANSI/NCSL Z540-1 1994. Our facilities are constantly monitored and audited by our Customers for compliance to their standards and are proud of our continued success in maintaining adherence to these stringent requirements.

Quality Systems Approvals include:

BAES | De Havilland |

Forming Approvals include:

| BAE | BAEP 4540 Forming Aluminum |

Boeing | BAC 5300 Forming Aluminum |

| Bombardier | PPS 1.02 Forming Aluminum |

Cessna / Textron | CSMP 017 Forming Sheet Metal / Extrusions |

Gulfstream | GAMPS 2101 Forming Aluminum |

| Lockheed | STP 51-302 Forming Sheet Metal / Extrusions STP 65096 Forming 7XXX Aluminum STP 75016 Forming 2XXX Aluminum LADC-P-70-1046 Sheet Metal |

Northrop/Grumman | PS 14.007 Forming Titanium *2 AXIS Water Jet Capability |

Special Process Approvals include:

| CUSTOMER | SPECIFICATION TITLE | SPEC |

| BAE | Heat Treating of Aluminum | BAEP 9004 BAEP 9006 BAEP 9081 BAEP 9088 BAEP 4638 |

| Boeing Commercial Boeing Military Boeing Defense & Space | Heat Treating of Aluminum Temper Inspection of Aluminum | BAC 5602 BAC 5946 BAC 5651 |

| Boeing / Douglas Commercial Boeing / Douglas Military | Heat Treating Aluminum | DPS 7.00-1 DPS 7.00-1-17 |

| Boeing / Douglas MTA | General Heat Treating of Aluminum | P.S. 15500 |

| Cessna | Anneal | CSMP003 |

| Goodrich | Heat Treating of Aluminum | RPS 12.31 |

| Gulfstream | Heat Treating of Aluminum | GAMPS 5108 |

| Lockheed Martin | Heat Treating of Aluminum | AMS-H-6008 / AMS 2770 |

| Northrop Commercial | Heat Treating of Aluminum | DPS 7.00-1 DPS 7.00-1-17 |

| Northrop Military | General Heat Treating of Aluminum | P.S. 15500 |

| Raytheon Aircraft | Heat Treating of Aluminum | AMS-H-6008 / AMS 2770 |

Tools & Techniques

Versaform Corporation takes pride in our commitment to employ manufacturing tools and techniques that combine the latest innovations with common sense. As we strive to exceed our Customer’s expectations we place special emphasis on;

- Human Resources – Versaform Corporation’s main facility is located in Oceanside, California where a large, experienced work force is available. Our work force is stable, labor relations are excellent and there is a positive, can do attitude that permeates throughout the company.

- Engineering Support – With years of experience in the design and manufacture of a wide variety of parts, components and assemblies, our Engineering support is unsurpassed within the manufacturing industry. Our years of knowledge can help with your design, simplify the start up process and minimize production costs for the life of your program.

- Information Technology – We have embraced information technology as a means to reduce turn around times and communicate more effectively with our Customers. Our information systems allow for the electronic data transmission of drawings and engineering specifications and are on line with capabilities to read wire frame and surface drawings that are compatible to most CAD type systems.

- Lean Activities – At Versaform Corporation, we have implemented the philosophy of Lean Manufacturing with the goal of 100% on time deliveries with zero defects. In developing and implementing a lean organization, our objective is to reduce costs through the removal of waste and simplification of processes with the end result being cost savings to our Customers. We have successfully educated our employees as lean thinkers and practice this methodology on a daily basis.

- Total Quality Management/Continuous Improvement – Despite the fact that Versaform Corporation enjoys a hard won reputation for the excellent quality of its products and corresponding low rejection rates, as a company, we continue to embrace an aggressive Total Quality Management and Continuous improvement program. The continued use of these aggressive programs assures that Versaform Corporation will remain committed to meeting the latest and most stringent requirements of our Customers while exploring new methods, equipment, processes and techniques to reduce costs and improve our performance.

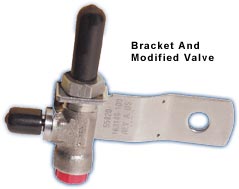

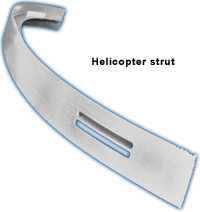

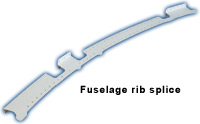

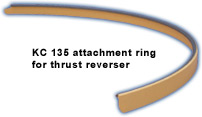

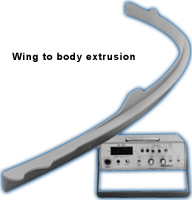

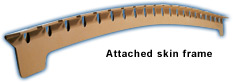

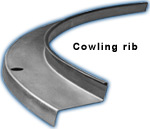

Aircraft/Aerospace Projects

Versaform has completed hundreds of successful projects for the aircraft and aerospace industries. Shown below are typical examples of our work.

|

Commercial Projects

Commercial work includes automotive, R.V. and bus equipment manufacturers, rail transportation, medical equipment and many more.

|  |  |

|  |

|  |

| |

Architectural Projects

We service extruderes, glazing and solarium manufacturers, contractors and architects.

|  |

|  |

| |

Stretch Forming

Stretch Forming is a time proven process used to form close tolerance shapes for the Aerospace, Military and Commercial industries. It is the primary method Versaform Corporation utilizes to form desired shapes and contours. This process allows us to create or duplicate any radii, complex contour or form using extruded shapes of varying profiles, flat sheets, square, rectangular, round or channel shapes, “I” beams or brake form shapes and offers the desired repeatability of shape from part to part.

|  |

|  |

Using this method, Versaform Corporation welcomes the challenge of difficult assignments.

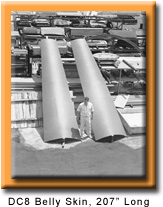

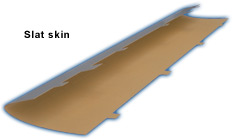

Skins

The forming of Skins is an integral part of the process of the manufacture of a modern commercial or business jet aircraft. If a modern jet aircraft was perfectly round and a constant cylinder from one end to the other and the wings and tail sections were of a consistent shape, the forming of these skins would be a simple process. As the shape of a jet aircraft varies from top to bottom, end to end, “simple processes” do not apply. The manufacture of these critical skins depends on a proven process that can offer repeatability while holding critical tolerances and maintaining the integrity of the skin surface.

This process employed is the forming of skins over dies of various shapes and contours. It allows for the forming of multiple, reverse or standard contours in varying types of materials such as aluminum, aluminum lithium, stainless steel and titanium at thicknesses from .020″ thick to over .100″ thick.

Versaform Corporation has extensive experience and expertise to form the most complex shapes, involving non-standard contours with the required repeatability and precision. Our experienced operators perform this process allowing for minimal or no distortion while maintaining the required critical skin surface.

|  |  |

Hydroforming

The forming capabilities at Versaform Corporation are further enhanced by employing the process of Hydro Forming, a relatively new method for manufacturing lightweight components. The Hydro Forming method uses environmentally friendly water to replace the rubber in the die cavity commonly used in Rubber Pad Forming.

This method allows for a more severe draw than in conventional methods because the pressure created by the water holds the metal tighter against the die surface to allowing for a more precise, repeatable forming process.

Stretch Draw Forming

Versaform Corporation is on the leading edge of this relatively new forming process Stretch Draw Forming. This process combines the two processes of Stretch Forming and Draw or Deep Draw Forming with excellent results involving the forming of complex or reverse contours. The implementation of this technique is replacing the outdated process of Drop Hammer forming.

The Stretch/Draw Form process is cleaner, quieter, more accurate and efficient and eliminates environmental concerns by removing Lead By-Products associated with the Drop Hammer process. Versaform Corporation is actively working with major Airframe Manufacturers to replace outdated Drop Hammer formed parts with parts produced using the advanced Stretch/Draw Form process.

|  |  |

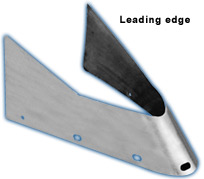

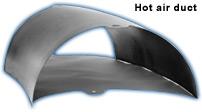

Leading

Continuing our process of implementing new technology, Versaform Corporation has developed a process for forming Leading Edges for aircraft that greatly reduces material usage and scrap while increasing repeatability and productivity.

We have developed a process that replaces the outdated Bump Forming or Stretch Forming process previously used. Our process guarantees a “net fit” to the forming die that is repeated from part to part and can be used to form Leading Edge shapes ranging from Large to Knife Edge configuration. Due to the dynamics of this forming process, the required Skin Quality surface finish associated with a Leading Edge is easily maintained.

Shear

|

Ring

|

Hot Cold

Joggling is a process used to apply offsets in a flat or curved plane, consisting of two parallel bends, in opposite directions within a part cross section. Joggles may be applied at room temperature or at elevated or reduced temperature depending on the depth and length of the joggle combined with the alloy type and gauge. Joggles may be applied using a Press Brake or during a Stretch Form operation.

Versaform Corporation offers the ability to form the required Joggles using any of the processes, hot, cold or room temperature while applying the Joggles using the Press Brake or Stretch Form method and maintaining the required tolerances and repeatability.

Waterjet

Versaform Corporation continues offers the latest cutting technology with the application of our Water Jet Cutting services. Water Jet Cutting offers an alternative to flame cutting, machining, rough cutting with band saws and shearing by using a computer controlled stream of water, applied at a high rate of speed to achieve the required precision detailed flat pattern, hole pattern or shape.

Versaform Corporation continues offers the latest cutting technology with the application of our Water Jet Cutting services. Water Jet Cutting offers an alternative to flame cutting, machining, rough cutting with band saws and shearing by using a computer controlled stream of water, applied at a high rate of speed to achieve the required precision detailed flat pattern, hole pattern or shape.

Water Jet Cutting can be applied to the thinnest of materials up to the thickest and as the cutting is accomplished with water, the process is environmentally friendly. There are few limitations with regards to the types of materials that can be cut using the Water Jet. Marble, Hardened Steel, Aluminum, Titanium, Kevlar, Wood, Copper and Glass are some of the materials to which we applied this process. Because the desired shapes or hole patterns are computer developed and controlled, repeatability from part to part is maintained with ease while holding tolerances within .005″ allowing for cost effective production runs.

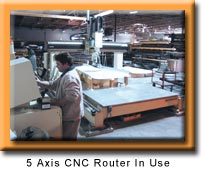

5 Axis CNC Routing

Enhancing our Cutting and Routing capabilities is our 5 Axis CNC Router. This Router has been designed to offer the latest technology in Routing and Drilling of hole patterns in large, formed aircraft skins. Employing vacuum fixtures to stabilize the skin, tolerances of +/- .003″ for the skin profile and +/- .010″ for the multiple hole patterns are easily maintained.Reduce man hours,Advantages of the 5 Axis

CNC Router include:

- Decreased Scrap,

- Reduced De-burring time,

- Increased accuracy

and repeatability, - Reduced costs.

Welding

|

Heat Treating

Versaform Corporation offers internal capabilities to perform Heat Treating, Annealing and Artificial Aging of skins, extrusions and sheet metal components and are accomplished at our Oceanside, California facility.

We are approved to perform these processes for virtually every major Airframe manufacturer in North America and overseas and offer the accompanying Hardness Testing capabilities required to maintain these approvals.

The advantage to performing these processes internally are:

- Lower costs

- Quicker lead times

- Lesser possibility of handling or transportation damage

- Ultimate control of the process which allows for the

necessary quality of the process

Tooling

Versaform Corporation offers an extensively experienced staff of full time tool makers which allows for the capability to repair customer tooling in house or offer services for the replacement of tools using the latest manufacturing technologies. In addition, we offer the ability to produce first time or new tooling using customer supplied hard copy or electronic design data.

Recognized for our quality of built tooling, Versaform Corporation has serviced the tooling needs of customers worldwide. Our internal tool build capability allows us to offer reduced lead times at lower costs while maintaining the required engineering requirements.

|

Fabrication

Ranging from the fabrication of a single piece component to complex, multiple quantity orders, Versaform Corporation offers the broad range of expertise necessary to address your company unique requirements.

Ranging from the fabrication of a single piece component to complex, multiple quantity orders, Versaform Corporation offers the broad range of expertise necessary to address your company unique requirements.

Our extensive abilities and fabrication services lend themselves to the manufacture of components, involving various types of materials that include but are not limited to composites, aluminum alloys and aluminum compounds, stainless steel, titanium, glass and marble.In addition, our ability to interpret programming from the latest computer generated data allows our Engineering department to develop and design intricate, complex and compound shapes.

|  |

Assemblies

The ability to assemble multiple detail components into larger, “Sub Assemblies” or “Finished Assemblies” is critical in the manufacture of a Commercial or Business Jet Aircraft. Versaform Corporation continues to offer “Full Service Capabilities” within this area using proven capabilities that assures our continued standing at the forefront of the latest industry standards.

The ability to assemble multiple detail components into larger, “Sub Assemblies” or “Finished Assemblies” is critical in the manufacture of a Commercial or Business Jet Aircraft. Versaform Corporation continues to offer “Full Service Capabilities” within this area using proven capabilities that assures our continued standing at the forefront of the latest industry standards.

Whether using customer supplied jigs and fixtures or our own internal abilities to manufacture the required tooling using customer supplied design criteria, the end results are the same, significant cost savings and greatly reduced delivery lead times passed on to the customer.

Whether using customer supplied jigs and fixtures or our own internal abilities to manufacture the required tooling using customer supplied design criteria, the end results are the same, significant cost savings and greatly reduced delivery lead times passed on to the customer.

Check

Sheet metal or extruded shapes are continually subjected to varying conditions throughout the manufacturing process including exposure to elevated or significantly reduce temperatures, varying limits of applied stress and multiple handling operations. These varying conditions may induce involuntary movement within the actual shape of the product resulting in a configuration that falls outside of the required engineering parameters.

Versaform Corporation offers extensive experience while employing state of the art equipment that allows for the quick and cost effective correction of the configuration anomaly thereby offering the customer a product that meets all engineering parameters.

Draw Forming

Draw Forming or Deep Draw Forming is the process of forming sheet metal components from aluminum alloy or stainless steel, between an edge-opposing punch and die, (draw ring), thereby producing the desired cup, cone, box or shell-like part configuration. The distinction between Draw Forming and Deep Draw Forming is generally related to the depth of the drawn shape versus the end result diameter or width.

In the application of standard or shallow Draw Forming, the process usually results in a shape no deeper than half its end width or diameter. Applying the Deep Drawing process will result in attaining a shape in which the depth generally exceeds more than half of the end width or diameter. As reduction (thinning) of the material thickness resulting from the draw process may occur, a multiple stage drawing process using 2, 3 or 4 individual steps may be required.

Versaform Corporation offers extensive experience in all applications of single and multiple stage Draw Forming. Our experienced Engineering Department allows for the accurate calculation of acceptable material reduction percentages to assure that the finished product meets our customers weight requirements while maintaining the necessary structural strength. The use of the draw forming technique can eliminate the requirement for the welding of seams or corners.

Stretch Form, Draw Form, Brake Form and Hydro Forming processes

The very latest materials technology and manufacturing systems are employed to produce complex structural components using aluminum, titanium and stainless steel alloys for application within the Aerospace, Military, Architectural and Commercial arenas. A skilled employment force using, the most advanced equipment available, perform the forming processes with the highest level of precision that meets and often exceeds the Customer specification requirements.

Formed shapes can be contoured from rectangular, round or square tubing, brake form sheet metal shapes such as angles and channels, extrusions, pressure plates, dome caps, ellipses and compound radii. Materials of various descriptions are used to form these shapes including but not limited to aluminum, stainless steel, copper, brass, muntz and carbon steel.

Draw Forming or Deep Draw Forming is the process of forming sheet metal components from aluminum alloy or stainless steel, between an edge-opposing punch and die, (draw ring), thereby producing the desired cup, cone, box or shell-like part configuration. The distinction between Draw Forming and Deep Draw Forming is generally related to the depth of the drawn shape versus the end result diameter or width.

In the application of standard or shallow Draw Forming, the process usually results in a shape no deeper than half its end width or diameter. Applying the Deep Drawing process will result in attaining a shape in which the depth generally exceeds more than half of the end width or diameter. As reduction (thinning) of the material thickness resulting from the draw process may occur, a multiple stage drawing process using 2, 3 or 4 individual steps may be required.

Joggling is a process used to apply offsets in a flat or curved plane, consisting of two parallel bends, in opposite directions within a part cross section. Joggles may be applied at room temperature or at elevated or reduced temperature depending on the depth and length of the joggle combined with the alloy type and gauge. Joggles may be applied using a Press Brake or during a Stretch Form operation.

Versaform Corporation manufacturers sheet metal components using the tried and true method of Shearing and Brake Forming the required cross sections. Brake Form components make up large portions of the structural components used in Commercial and Business jet aircraft as well as structural and trim pieces for Architectural and Commercial building use. The use of multiple forming dies with varying bend radii size, allows our experienced operators to form a multitude of shapes at lengths up to 12 feet while holding critical tolerances throughout the length of the shape. These shapes can be formed from a multitude of material types including aluminum, stainless steel, and titanium.

Versaform Corporation manufacturers sheet metal components using the tried and true method of Shearing and Brake Forming the required cross sections. Brake Form components make up large portions of the structural components used in Commercial and Business jet aircraft as well as structural and trim pieces for Architectural and Commercial building use. The use of multiple forming dies with varying bend radii size, allows our experienced operators to form a multitude of shapes at lengths up to 12 feet while holding critical tolerances throughout the length of the shape. These shapes can be formed from a multitude of material types including aluminum, stainless steel, and titanium.

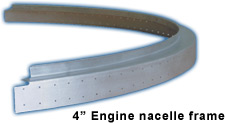

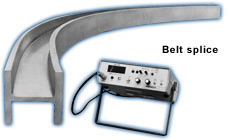

Versaform Corporation employs two processes for the precise forming of Rings, Cylinders and Truncated Cones. The process of Ring Roll Forming is used to form plate, sheet metal sections, bars, beams, angles or extrusions into circular shapes. Rings may be formed starting with straight sections or by taking preformed rings and expanding or contracting the existing diameter to the required size. The process of Roll Forming is used to form constant Cylinders or Truncated Cones from varying thicknesses of sheet aluminum or stainless steel. These types of processes take advantage of favorable grain flow direction, offer material savings and are capable of producing close tolerances which repeat from part to part.

Versaform Corporation employs two processes for the precise forming of Rings, Cylinders and Truncated Cones. The process of Ring Roll Forming is used to form plate, sheet metal sections, bars, beams, angles or extrusions into circular shapes. Rings may be formed starting with straight sections or by taking preformed rings and expanding or contracting the existing diameter to the required size. The process of Roll Forming is used to form constant Cylinders or Truncated Cones from varying thicknesses of sheet aluminum or stainless steel. These types of processes take advantage of favorable grain flow direction, offer material savings and are capable of producing close tolerances which repeat from part to part. Versaform Corporation offers a wide range of welding capabilities including MIG, TIG and Resistance Welding. These process are applied to perform accurate assembly of detail aircraft components manufactured from various types of material thereby saving our customers time and inventory costs. Welding Certifications include AMS-STD-1595, MIL-W-6858D, MIL-STD-2219 Aluminum, Stainless Steel and Hastelloy.

Versaform Corporation offers a wide range of welding capabilities including MIG, TIG and Resistance Welding. These process are applied to perform accurate assembly of detail aircraft components manufactured from various types of material thereby saving our customers time and inventory costs. Welding Certifications include AMS-STD-1595, MIL-W-6858D, MIL-STD-2219 Aluminum, Stainless Steel and Hastelloy.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services