Stability chambers are rooms that are specifically designed for product testing under controlled environmental conditions. These chambers are also used to determine the shelf life of products such as drugs, electrical components, and industrial materials. It is required to keep the climatic conditions of temperature and humidity under control. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

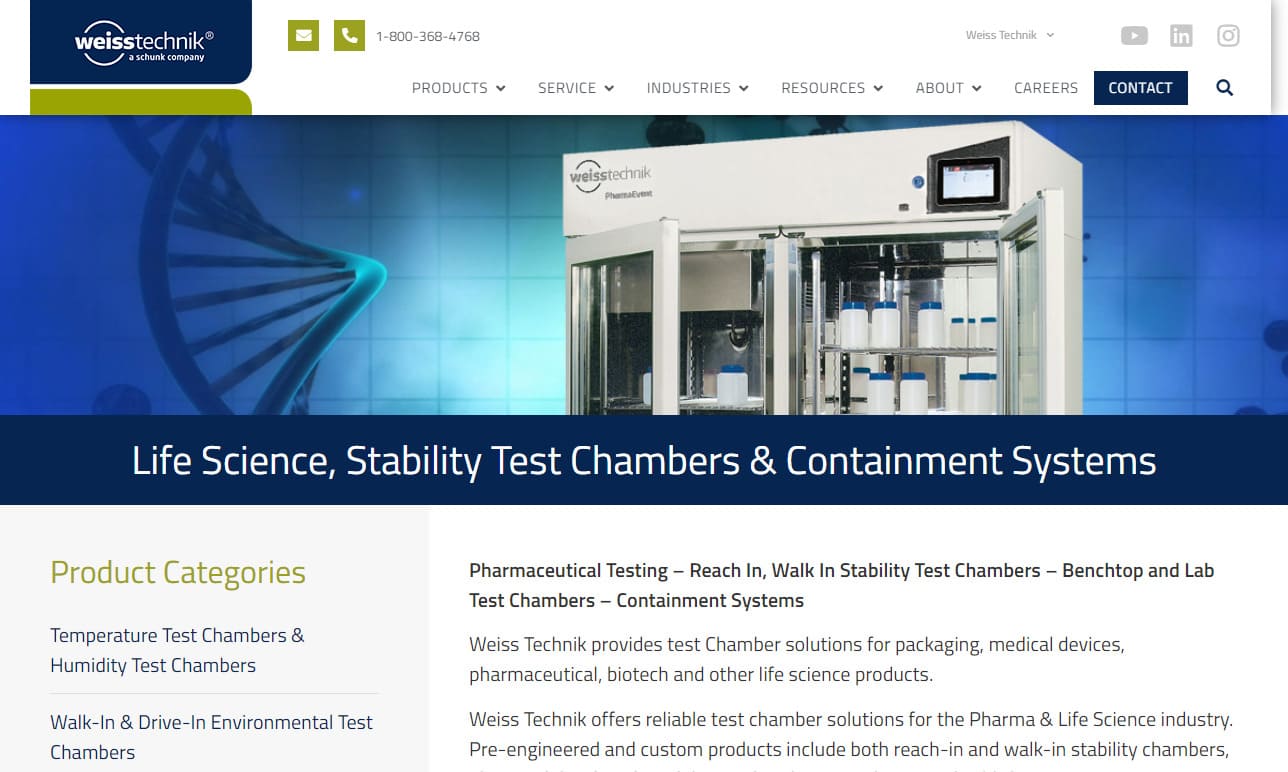

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

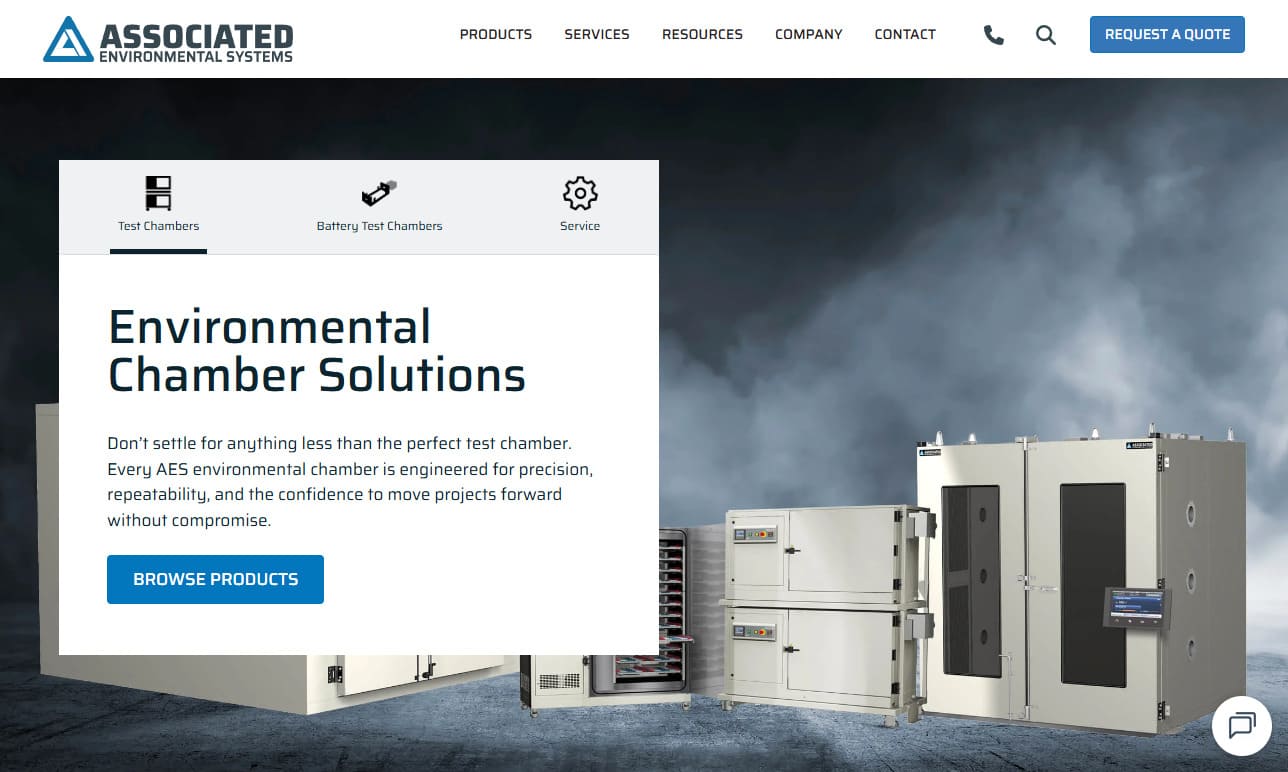

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

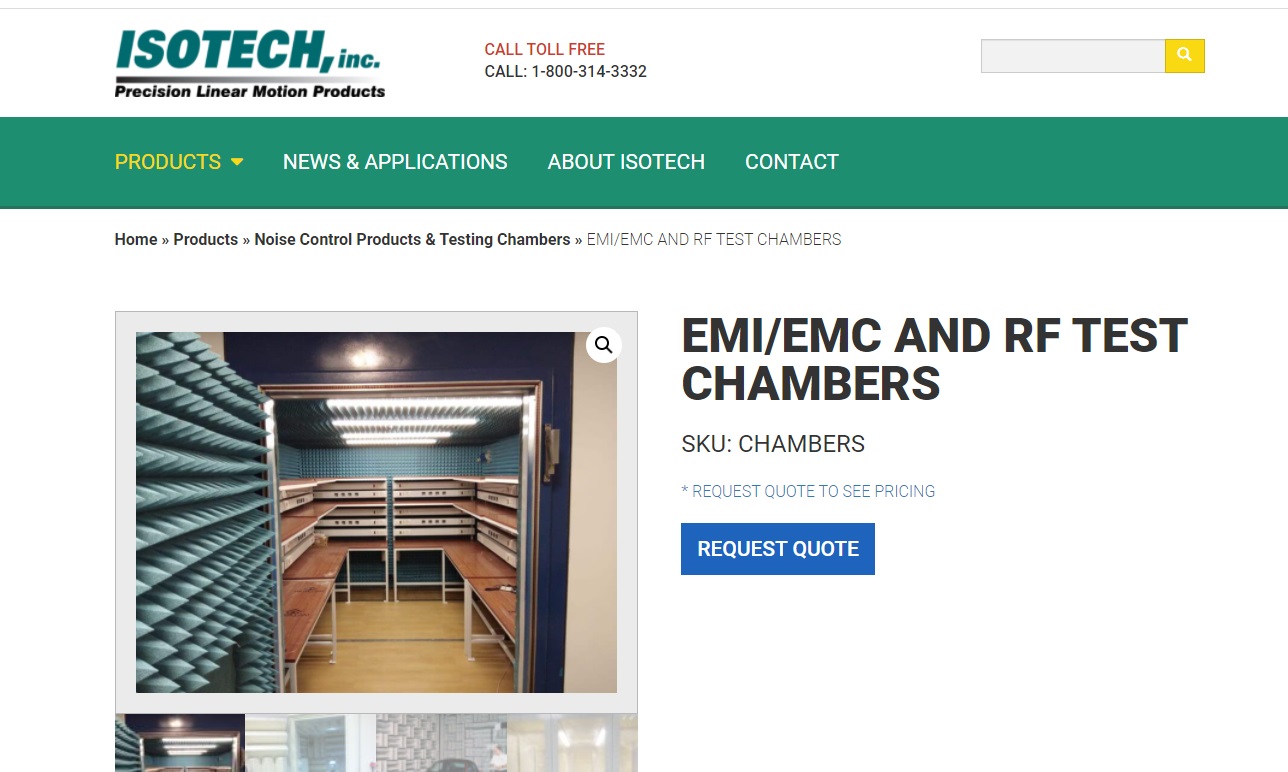

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Stability Chamber Manufacturers

What Are Stability Chambers?

Stability chambers, also known as environmental stability test chambers or stability testing chambers, are highly specialized pieces of laboratory equipment designed to create controlled and repeatable environmental conditions. These advanced chambers allow manufacturers and researchers to accurately simulate a wide range of temperature, humidity, and lighting parameters for the testing and evaluation of pharmaceuticals, chemicals, cosmetics, electronic components, food products, and more. By precisely controlling environmental variables, stability chambers play a critical role in product development, quality assurance, and regulatory compliance across numerous industries.

Because different products and materials require unique environmental testing conditions, it is not practical or cost-effective to physically relocate samples to various global climates. Instead, stability chambers provide a flexible, efficient, and consistent testing solution by enabling the creation of customizable environmental conditions within a single, secure unit. This versatility makes stability chambers indispensable for accelerated aging, shelf-life determination, stress testing, and long-term product stability studies.

Construction of Stability Chambers

Modern stability chambers are engineered for durability, precision, and ease of use. Their construction incorporates several key design elements to ensure reliable performance and user safety in laboratory and industrial settings. When researching stability chamber design and build quality, consider the following typical features:

- The exterior of the stability chamber is constructed from high-grade, anti-corrosive stainless steel, providing robust protection against chemical exposure, humidity, and temperature swings often encountered in laboratory and industrial environments.

- Some chamber models feature a glass front or observation window, enabling convenient monitoring of test samples without disrupting the internal environmental conditions or risking contamination.

- The chamber’s rigid stainless steel frame is precisely assembled using bolts and nuts for structural integrity, minimizing vibration and ensuring long-term reliability.

- An advanced thermal insulation layer is sandwiched between the exterior and interior panels to maintain stable internal temperatures, reduce energy consumption, and prevent heat transfer.

- Multiple adjustable steel mesh trays or shelves are provided, allowing flexible sample placement and maximizing usable space for different testing needs.

- Integrated temperature and humidity control systems utilize high-accuracy sensors, digital controllers, and feedback mechanisms to maintain precise setpoints.

- Eco-friendly, CFC-free refrigeration compressors provide reliable cooling while minimizing environmental impact and complying with modern regulations.

- Air heaters and forced air circulation systems ensure uniform heat distribution, rapid temperature recovery, and stable thermal gradients throughout the chamber interior.

- Safety features such as LED interior lighting, over-temperature alarms, door locks, and emergency shutoff systems keep operators and samples safe during prolonged test cycles.

Working Principle of Stability Chambers

Stability chambers function by maintaining highly controlled environmental parameters—including temperature, relative humidity (RH), air flow, and sometimes light exposure—according to strict industry guidelines. Understanding the working principle of stability chambers is essential for ensuring accurate, repeatable, and regulatory-compliant results.

- Stability chambers operate based on the principle of relative humidity, which describes the amount of water vapor present in the air compared to the maximum amount the air can hold at a specific temperature.

- By carefully balancing temperature and humidity, the chamber can replicate a wide range of climatic conditions, from tropical to arid to temperate environments.

- Increased temperatures raise the air’s capacity to hold moisture, which can decrease relative humidity unless additional water vapor is introduced into the chamber air stream.

- According to International Council for Harmonisation (ICH) guidelines—such as ICH Q1A(R2) for pharmaceutical stability testing—chamber temperature should not fluctuate more than 1–2°C from the setpoint, and relative humidity should remain within ±5% of the nominal value.

- Precision sensors continuously monitor chamber conditions, enabling the control system to automatically adjust heating, cooling, humidification, and dehumidification elements as needed to maintain stability.

- Uniformity is enhanced by horizontal laminar air flow, which distributes conditioned air evenly across all shelves and samples and prevents hot or cold spots.

- Exhaust ports or venting systems are incorporated for the periodic removal of exhaust air and to prevent pressure build-up, further ensuring a stable and safe testing environment.

Types of Stability Chambers

Stability chambers are available in multiple configurations, each optimized for specific testing applications and industry requirements. When exploring which stability chamber is right for your needs, consider the following major types:

-

Environmental Chambers

Environmental chambers, sometimes called climate simulation chambers, are used to detect product defects and assess durability by simulating a diverse range of environmental conditions. These testing chambers can replicate dry, humid, corrosive, rainy, or dusty environments, and are capable of subjecting samples to fluctuating temperatures, humidity cycles, UV exposure, and even altitude or pressure variations. Commonly used in electronics, automotive, aerospace, materials science, and packaging industries, environmental chambers help ensure product reliability in real-world applications.

-

Temperature-Humidity Chambers

Temperature-humidity chambers—also referred to as climatic test chambers or climate chambers—allow for the simulation of specific temperature and humidity profiles to study their effects on product stability, performance, and lifespan. These chambers are available in a wide range of sizes, from compact benchtop models to large walk-in rooms, and can achieve temperature ranges from 163.4°F (73°C) up to 374°F (190°C), with humidity control spanning from 10% to 98% RH. Use cases include testing of telecommunications equipment, photovoltaic solar panels, medical devices, and food packaging, where both temperature and moisture resilience are critical factors.

-

Accelerated Testing Chambers

Accelerated testing chambers, sometimes called accelerated aging chambers or stress test chambers, are designed to expose products and materials to intensified environmental stressors—such as elevated temperatures, high humidity, or increased UV light—over short periods of time. This enables rapid assessment of product durability, shelf life, expiration dates, and potential failure modes, often in accordance with regulatory standards (e.g., ASTM, FDA, ICH). Industries ranging from pharmaceuticals and food processing to electronics and polymers rely on accelerated testing chambers to bring products to market faster, while ensuring quality and safety.

-

Photostability Chambers

Photostability chambers are purpose-built for evaluating the effects of light exposure—especially UV and visible light—on sensitive materials such as pharmaceutical drugs, chemicals, cosmetics, and food products. These chambers tightly regulate temperature, humidity (when required), and light intensity, using fluorescent or LED lamps to mimic daylight conditions. Photostability testing is essential for determining how products degrade under light, supporting label claims, expiration dating, and regulatory submissions. Safety interlocks, such as automatic shutoff of lights when the chamber door is opened, protect users and ensure consistent test results.

Stability Chambers: Common Applications by Industry

Stability chambers are essential across a wide range of sectors for ensuring product quality, safety, and regulatory compliance. When considering where stability chambers are used, here are some common industry applications:

- Pharmaceuticals & Biotechnology: Critical for drug stability testing, shelf-life studies, and ICH-compliant trials to determine expiration dates, degradation profiles, and packaging effectiveness under controlled conditions.

- Food & Beverage: Used for accelerated shelf-life testing, microbial stability, packaging validation, and sensory evaluation to ensure product freshness, safety, and compliance with FDA and HACCP requirements.

- Cosmetics & Personal Care: Employed in stability testing of creams, lotions, and cosmetic products to evaluate performance, ingredient compatibility, and packaging interactions under varying climate scenarios.

- Electronics & Semiconductor: Utilized to test the durability and reliability of circuit boards, semiconductors, and electronic components under temperature and humidity stress, often as part of quality control or MIL-STD qualification.

- Automotive & Aerospace: Used to verify the resilience of automotive parts, aerospace materials, and systems exposed to environmental extremes, vibration, and humidity cycles.

- Industrial Materials & Polymers: Applied in accelerated aging studies, weathering tests, and mechanical integrity assessments of plastics, rubber, adhesives, and composites.

- In addition, stability chambers play a key role in research labs, universities, and government testing agencies for fundamental scientific studies, product innovation, and regulatory submissions.

Choosing a Stability Chamber

Choosing the right stability chamber is a crucial investment for any laboratory or manufacturing facility. The selection process should focus on matching the chamber’s technical capabilities to your specific application, sample volume, regulatory requirements, and long-term testing goals.

Key Factors to Consider When Selecting a Stability Chamber

-

Temperature Range

Temperature control is fundamental in stability testing. It is important to choose a stability chamber that covers the required testing temperature range, whether for accelerated aging, freeze-thaw cycles, or long-term storage. Consider the minimum and maximum temperature setpoints, temperature uniformity, and recovery speed after door openings.

-

Humidity Range

Humidity precision is equally vital, especially for pharmaceutical, food, and electronics testing. Look for chambers that offer accurate and stable humidity control across the necessary RH range, with reliable dehumidification and humidification systems. Be sure to check if the chamber supports programmable humidity profiles for complex test protocols.

-

Chamber Size & Configuration

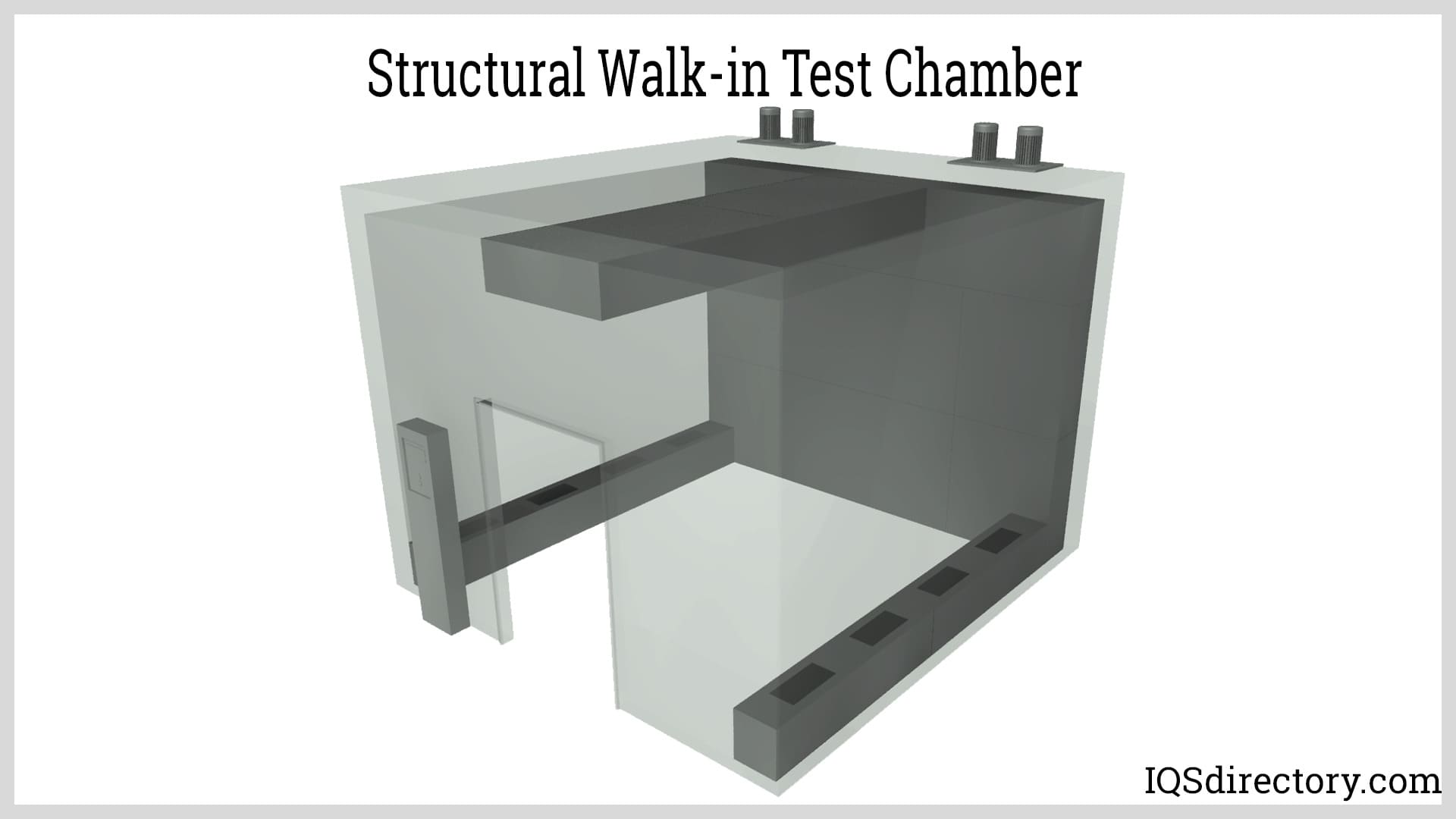

Chamber size directly impacts throughput and operational efficiency. Evaluate whether a compact benchtop (reach-in) chamber, a mid-sized floor-standing unit, or a large walk-in chamber is best for your sample volume and workflow.

-

Reach-in Chambers

These are small, cabinet-like stability chambers suitable for limited sample quantities, R&D applications, or pilot-scale testing. Reach-in chambers are space-efficient, cost-effective, and easy to operate.

-

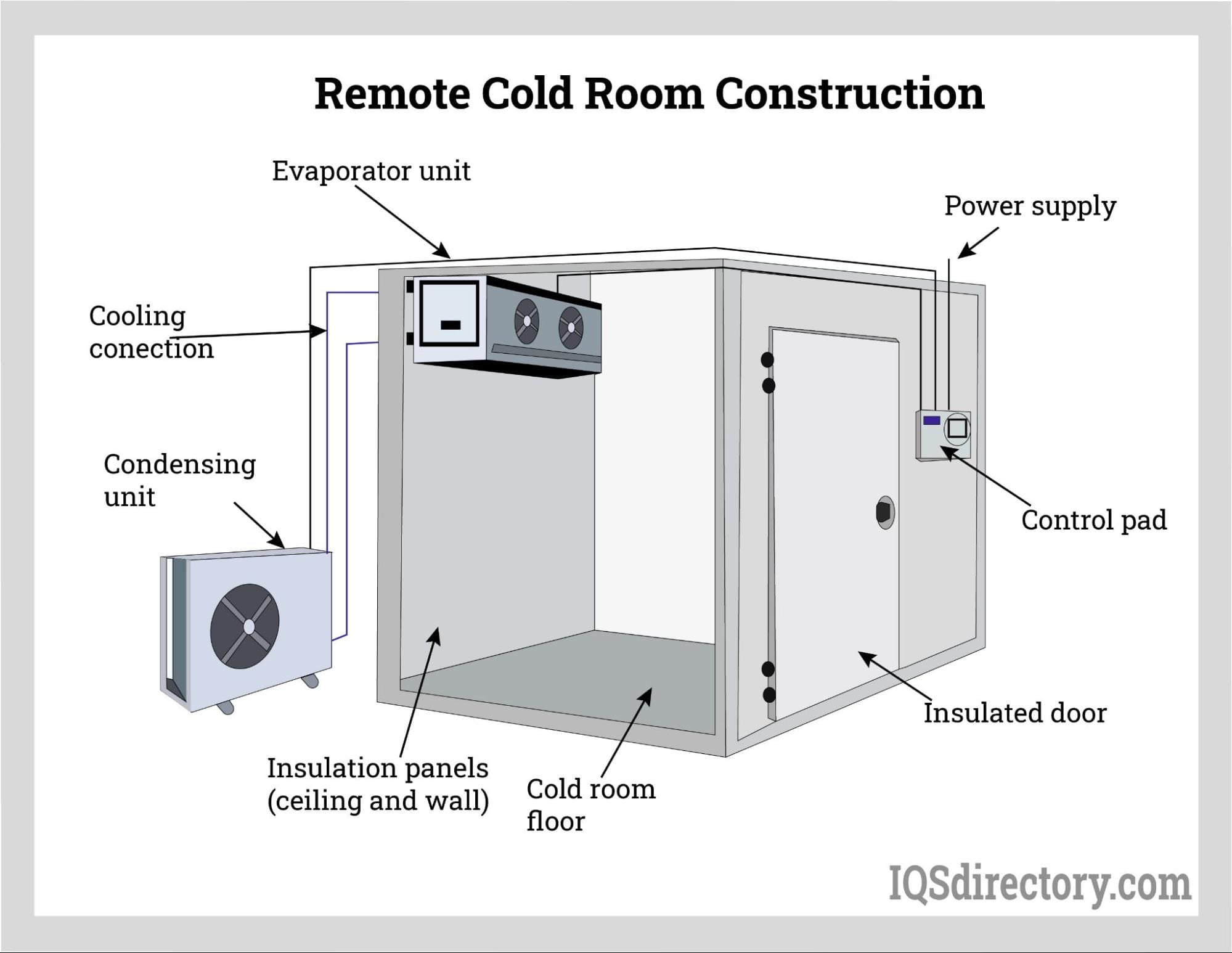

Walk-in Chambers

Walk-in chambers provide ample storage for large-scale stability studies, bulk material testing, or high-throughput screening. These spacious chambers can be custom-configured with multiple shelves, lighting systems, and access ports, making them ideal for pharmaceutical manufacturers, food processing plants, and high-volume laboratories.

-

-

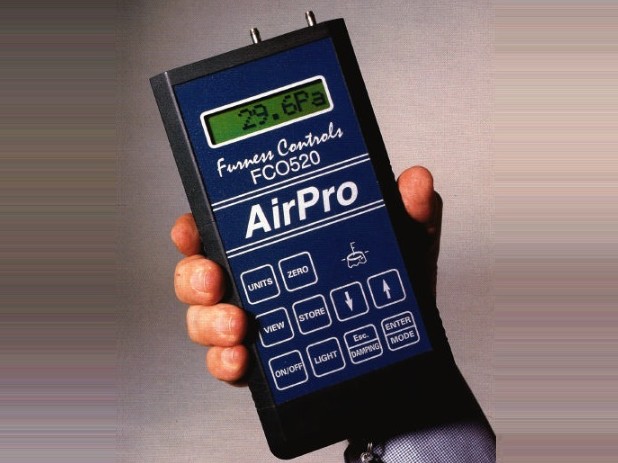

Control System & User Interface

Modern stability chambers feature advanced digital controllers with touchscreen interfaces, programmable test profiles, real-time data logging, remote monitoring, and integration with laboratory information management systems (LIMS). Evaluate the ease of use, data export capabilities, and alarm features to ensure compliance and operational efficiency.

-

Compliance & Validation

For regulated industries—such as pharmaceuticals, biotechnology, and food—ensure the chamber is designed and documented to meet relevant standards (e.g., ICH, FDA, GMP, GLP, ASTM). Look for features such as validation documentation, calibration certificates, and audit trail functionality.

-

Energy Efficiency & Environmental Impact

Consider energy-efficient design elements such as high-performance insulation, LED lighting, and eco-friendly refrigerants. These features not only reduce operational costs but also support sustainability initiatives and regulatory compliance.

-

After-Sales Support & Maintenance

Reliable technical support, regular calibration, spare parts availability, and maintenance services are essential for minimizing downtime and ensuring long-term performance of your stability chamber.

Frequently Asked Buyer Questions

- What is the difference between a stability chamber and an environmental chamber? – While both simulate environmental conditions, stability chambers are optimized for long-term, tightly controlled storage and testing, whereas environmental chambers offer broader simulation for accelerated or destructive testing.

- How do I determine the right chamber size for my application? – Assess your sample volume, available laboratory space, and anticipated future testing needs. Contacting a manufacturer for a needs assessment can help match you with the appropriate reach-in or walk-in model.

- Which regulatory standards apply to stability chambers? – Depending on your industry, relevant standards may include ICH Q1A(R2), FDA 21 CFR Part 11, GMP, GLP, and ASTM guidelines. Consult with the manufacturer for compliance documentation and validation services.

- How often should stability chambers be calibrated? – Regular calibration, at least annually or as required by your quality system, is essential for maintaining accuracy and compliance. Many manufacturers offer calibration and maintenance contracts.

- What are typical lead times for custom stability chambers? – Lead times vary by manufacturer and project complexity. Standard models may be available within weeks, while custom-engineered chambers can require several months. Planning ahead is recommended.

Choosing the Correct Stability Chamber Manufacturer

To ensure the most beneficial outcome when purchasing a stability chamber from a reputable stability chamber manufacturer, it is important to compare several companies using our comprehensive directory of stability chamber manufacturers. Each manufacturer’s profile page highlights their areas of expertise, product capabilities, and certifications, along with a convenient contact form to request additional information or a personalized quote.

You can easily review each stability chamber business website using our patented website previewer to quickly identify manufacturers that specialize in your target application—whether for pharmaceutical, food, electronics, or industrial testing. Use our simple RFQ (Request for Quote) form to contact multiple stability chamber companies simultaneously and obtain competitive pricing, lead times, and technical proposals. This streamlined process helps ensure you select a manufacturer that meets your unique requirements for chamber size, performance, compliance, and after-sales support.

How to Get Started

- Explore our directory of stability chamber manufacturers and filter by product type, industry focus, or certification requirements.

- Review each manufacturer’s business profile and capabilities, paying attention to experience with your specific testing applications and regulatory environment.

- Use the website previewer to efficiently compare offerings, technical specifications, and reference projects.

- Submit a single RFQ to reach multiple qualified vendors and request detailed proposals tailored to your needs.

- Discuss your requirements with manufacturers, including temperature and humidity ranges, chamber size, compliance needs, and optional features such as data logging, remote access, or custom shelving.

- Request validation documentation, maintenance agreements, and training resources as part of your purchase decision.

Ready to Find the Right Stability Chamber?

Begin your search by visiting our directory or contacting our team for expert assistance. Discover the best stability chamber solution for your laboratory, production facility, or research program—ensuring precise environmental control, regulatory compliance, and reliable product testing for years to come.

Want to Learn More?

- How do stability chambers compare with other types of environmental test chambers?

- What are best practices for maintaining long-term sample integrity in stability testing?

- How can you optimize energy efficiency and reduce operating costs in your lab?

- What are the latest trends in stability chamber technology, such as IoT integration and remote monitoring?

- Looking for case studies on successful stability testing in pharmaceuticals, food, or electronics?

Explore our resource library or reach out to our experts to take the next step in your stability testing journey.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services