An environmental chamber or climatic chamber is an enclosed area that is used to test the effects of particular environmental conditions on industrial products, machine components, electronics, and biological items. These climatic chambers are designed to artificially control certain conditions such as heat and humidity. Any environmental condition can be created artificially, such as an extremely hot, cold, or even corrosive environment. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Environmental Chambers Manufacturers

Environmental Chambers: Comprehensive Guide to Testing, Applications, and Selection

Environmental chambers, also known as environmental test chambers, are specialized enclosures designed to simulate a wide range of environmental conditions for product testing and quality assurance. These chambers play a critical role in research and development, manufacturing, and quality control processes across industries. By providing controlled settings for temperature, humidity, altitude, vibration, and other factors, environmental test chambers enable engineers, scientists, and manufacturers to evaluate how products, materials, or components perform under real-world and extreme conditions. This guide explores the types, working principles, industry applications, and key considerations for sourcing the right environmental chamber for your needs.

What Conditions Can Environmental Chambers Simulate?

Environmental chambers are engineered to replicate a diverse array of climatic and physical environments. Depending on the test requirements, the conditions may include:

- Extreme temperatures (hot and cold)

- Rapid temperature cycling and thermal shock

- Controlled altitude and low-pressure simulation

- Moisture, relative humidity, and dew point conditions

- Corrosion resistance testing (e.g., salt spray or salt fog)

- Exposure to rain, water ingress, and weathering

- Vacuum environments for space or aerospace simulation

- Solar radiation and UV aging

- Dust, sand, and particulate testing

- Vibration and shock simulation

- Noise and acoustics (in anechoic chambers)

The manufactured specimen is introduced into the chamber, and precise environmental conditions are applied according to test protocols or regulatory standards. The sizes of test chambers can vary from compact benchtop units of 1 cubic foot (30cm) to large walk-in and drive-in chambers up to 12,000 cubic feet (3,600 m3), accommodating products from microelectronics to satellites and vehicles.

Working Principle of Climatic and Environmental Chambers

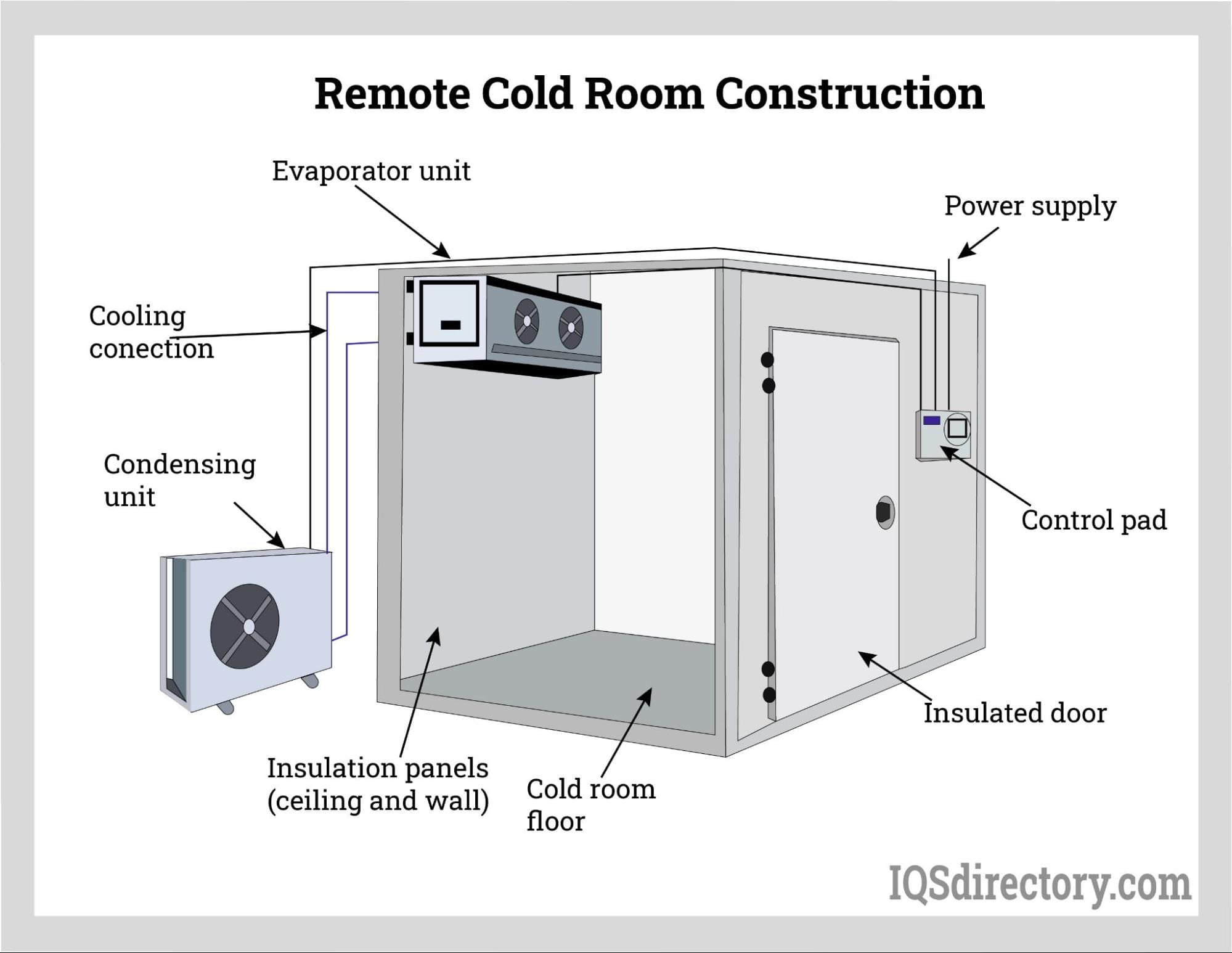

Environmental chambers operate by creating and regulating a set of environmental parameters within a sealed enclosure, allowing for repeatable and precise simulation of real-world conditions. The core functions and technologies include:

- All parameters (temperature, humidity, pressure, etc.) are controlled via programmable logic controllers (PLCs), touchscreens, or manual adjustments, depending on the model.

- Temperature is regulated using electric resistors, refrigeration compressors, or thermoelectric cooling/heating systems to achieve rapid or gradual changes.

- Water vapor is introduced through steam generators or atomizers for high humidity simulation.

- Humidity levels are precisely adjusted using ultrasonic humidifiers, water evaporation with heat, or desiccant drying systems for low humidity conditions.

- Corrosive atmospheres are produced by automated salt spray (fog) emitters for accelerated corrosion and rust testing.

- Vibration and shock are delivered by integrated electrodynamic or mechanical shakers, often synchronized with other environmental parameters for combined testing.

- Not every test chamber can simulate all conditions; specialized chambers are engineered for specific test requirements (e.g., thermal shock, vacuum, altitude).

- Advanced data logging and remote monitoring capabilities allow for real-time analysis and compliance documentation.

Looking to understand how environmental chambers work in your application? Ask: How can I simulate multiple environmental stresses for my product testing?

Types of Environmental Chambers

Environmental chambers are categorized by the environmental conditions they simulate and their core test functions. The primary types include:

Temperature Chambers

- Temperature test chambers are fundamental for assessing a product's durability under extreme temperatures. These tests may last days or weeks and reveal thermal resilience, expansion/contraction effects, and operational reliability.

- Also known as thermostatic or thermal cycling chambers, they cover wide temperature ranges from -94°F (-70°C) to 356°F (180°C).

- Common in electronics, automotive, and aerospace industries for lifecycle and reliability testing.

Humidity Chambers

- Humidity test chambers evaluate a product’s performance under various levels of relative humidity, often in combination with temperature cycling.

- Crucial for electronics, pharmaceuticals, and packaging to assess moisture ingress, corrosion, and condensation risks.

- Testing can be performed in static or dynamic conditions to simulate real-world use or storage scenarios.

Vibration Chambers

- Vibration test chambers subject products to controlled mechanical or electrodynamic shaking along one or more axes.

- Simulates transportation, operational, and accidental shocks to evaluate fatigue, structural integrity, and assembly robustness.

- Often combined with temperature or humidity for Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS).

Stability Chambers

- Stability chambers maintain tightly regulated temperature and humidity to study the shelf-life, degradation, and storage stability of pharmaceuticals, chemicals, and food products.

- Used for long-term and accelerated aging studies in compliance with industry standards (e.g., ICH, FDA guidelines).

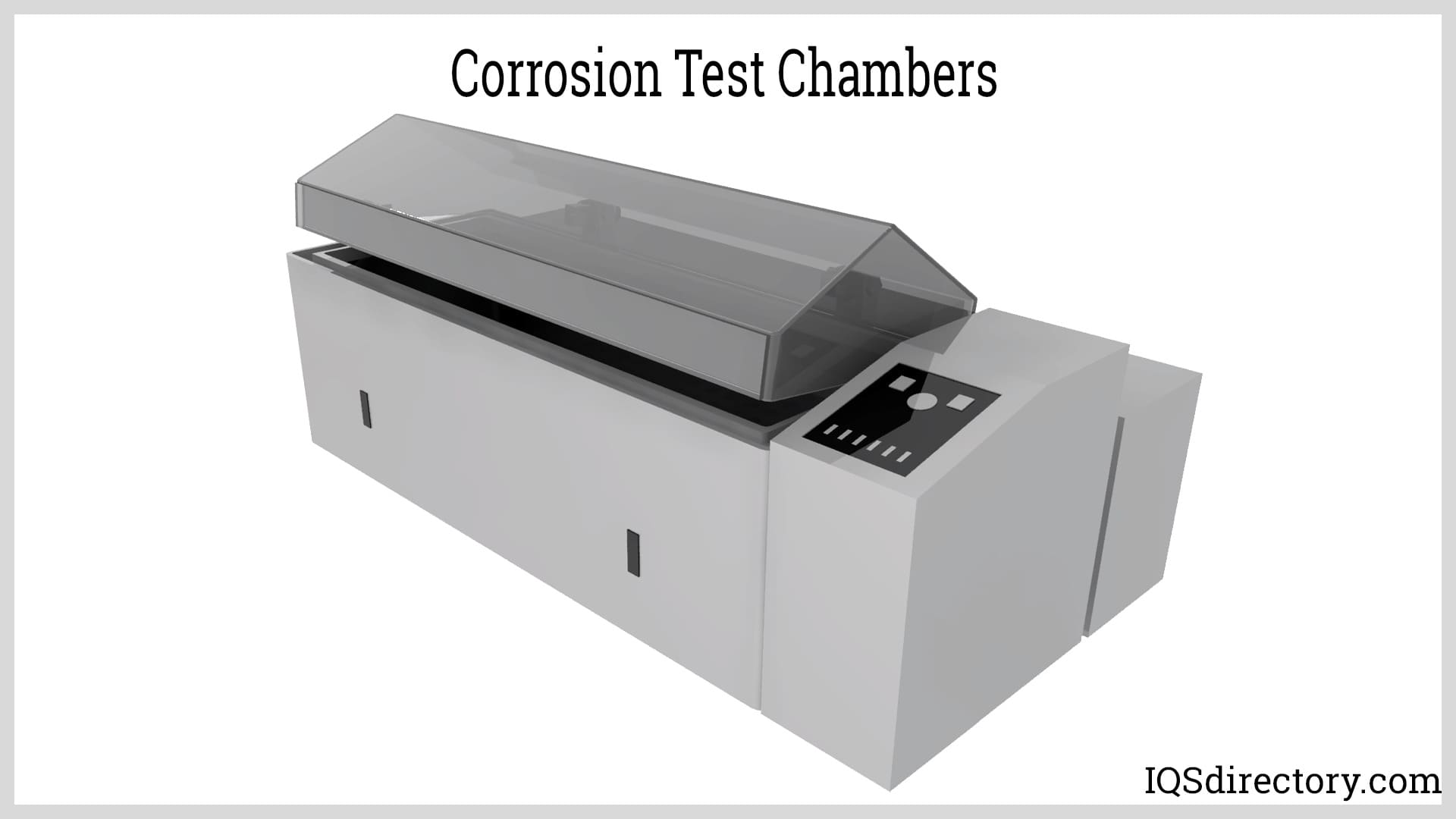

Corrosion Test Chambers

- Corrosion (salt spray) chambers assess the resistance of materials and coatings to aggressive environments, typically using sodium chloride mist.

- Critical for automotive, marine, and construction components to validate anti-corrosion treatments and paint finishes.

- Supports compliance with ASTM B117 and other international corrosion test methods.

Thermal Shock Chambers

- Thermal shock chambers rapidly transfer products between extreme hot and cold zones to reveal weaknesses caused by thermal expansion and contraction.

- Test protocols may demand temperature shifts of 86°F (30°C) or more per minute, simulating real-life exposure to sudden climate changes.

- Ideal for electronic components, glass, metals, and composite materials testing.

Vacuum Chambers

- Vacuum test chambers create low-pressure environments to simulate high-altitude or space applications, essential in aerospace, defense, and satellite manufacturing.

- Allows outgassing studies, pressure cycling, and leak testing under vacuum conditions.

- Supports qualification of materials and assemblies for space missions and aviation equipment.

Altitude Chambers

- Altitude test chambers simulate low-pressure, high-altitude environments up to 98,000 ft (30,000 m) for testing aerospace, defense, and telecommunications products.

- Capable of decompression, explosive decompression, and combined altitude-temperature-humidity testing.

- Used for avionics, aircraft components, and automotive systems validation.

Anechoic Chambers

- Anechoic test chambers are designed for acoustic and electromagnetic interference (EMI/EMC) testing, eliminating echoes and external noise.

- Used for measuring sound emissions, radio frequency interference, and electromagnetic compatibility in electronics, automotive, and telecommunications devices.

- Walls lined with sound-absorbing or RF-absorbing materials for accurate, repeatable measurements.

Industry Applications: Who Uses Environmental Test Chambers?

Environmental chambers are essential tools in a variety of industries, supporting compliance, innovation, and product reliability. Key sectors include:

Automotive Industry

Automotive manufacturers utilize environmental chambers to verify the reliability and life expectancy of components—such as engines, batteries, and electronics—prior to assembly and market launch. Testing encompasses thermal cycling, vibration, humidity, and salt spray to simulate real-world driving conditions and ensure compliance with ISO and SAE standards.

Electronics Industry

Electronic devices, printed circuit boards (PCBs), semiconductors, and sensors are tested in environmental chambers for resistance to heat, humidity, corrosion, and vibration. This prevents field failures, ensures consistent performance, and accelerates time-to-market for consumer electronics, industrial controls, and critical infrastructure components.

Pharmaceutical Industry

Pharmaceutical manufacturers use stability and humidity chambers to determine the shelf-life, efficacy, and storage requirements of drugs, vaccines, and medical formulations. Tests comply with global regulatory standards (e.g., ICH Q1A(R2)) to ensure safety and effectiveness.

Medical Device Manufacturing

Medical devices and implants are subjected to simulated environmental stresses—including temperature, humidity, and sterilization cycles—to ensure patient safety and product reliability in diverse clinical environments.

Defense & Military

Military and defense contractors test equipment for survivability in extreme climates, elevated altitudes, and under mechanical shock and vibration. Environmental qualification is critical for mission readiness and compliance with MIL-STD standards.

Telecommunications

Telecommunications hardware, such as satellites, antennas, and network infrastructure, undergoes environmental testing for altitude, temperature, humidity, and vibration to validate performance in remote or harsh locations.

Solar and Renewable Energy

Solar panels, wind turbine components, and batteries are evaluated for durability under UV exposure, temperature cycles, humidity, and salt fog, ensuring long-term reliability in outdoor installations.

Aerospace Industry

The aerospace sector relies on vacuum, altitude, and thermal cycling chambers to qualify satellite components, avionics, and spaceflight hardware for operational reliability in the harsh conditions of space and upper atmosphere.

Curious how your sector can benefit from environmental testing? Explore: What industry standards require environmental chamber testing in my field?

Chamber Sizes and Configurations: From Benchtop to Walk-In

Environmental test chambers come in a variety of sizes and configurations to suit different sample sizes and use cases. The three main types by size are:

Bench-Top Chambers

Benchtop environmental chambers, ranging from 0.5 to 5.5 cubic feet (15 to 156 liters), are ideal for laboratory research, quality control, and small-scale product development. Compact and energy-efficient, they offer flexibility for testing small components, PCBs, or sample materials.

Reach-In Chambers

Reach-in chambers, typically sized between 4 and 70 cubic feet (113 to 1,980 liters), are versatile units capable of simulating temperature, humidity, vibration, and other conditions. They are widely used for batch testing, accelerated life testing, and mid-scale product validation.

Walk-In and Drive-In Chambers

Walk-in and drive-in environmental chambers offer expansive volumes, allowing for the testing of large assemblies, finished products, or multiple samples simultaneously. Common in the automotive, aerospace, and electronics industries, these chambers support custom test protocols and high-throughput validation. Sizes can accommodate anything from racks of electronics to entire vehicles or satellites.

Benefits of Environmental Testing Chambers

- Product Reliability: Identify design flaws, weak materials, and potential failure modes before market release.

- Regulatory Compliance: Meet industry-specific testing standards (e.g., ASTM, MIL-STD, IEC, ISO, FDA) for safety, quality, and performance.

- Accelerated Aging: Simulate years of wear and environmental exposure in a matter of weeks or months, enabling faster product development cycles.

- Repeatability: Achieve consistent, measurable, and traceable results with programmable test profiles and data logging.

- Versatility: Test a wide range of products, from microelectronics to heavy vehicles, under various environmental stresses.

- Risk Mitigation: Reduce warranty claims, product recalls, and liability by proactively identifying vulnerabilities.

- Market Advantage: Demonstrate product durability and quality to customers and differentiate from competitors.

Ready to improve your product’s reliability? Ask: What types of environmental chamber tests are required for my certification and market launch?

Key Factors in Selecting an Environmental Chamber

- Test Requirements: Identify the environmental parameters (temperature, humidity, vibration, altitude, etc.) relevant to your product and industry standards.

- Chamber Size & Capacity: Choose a chamber that accommodates your largest test sample and any required test fixtures.

- Performance Specs: Consider temperature and humidity ranges, ramp rates, uniformity, and control accuracy.

- Control & Monitoring: Look for user-friendly interfaces, remote monitoring, programmable profiles, and robust data logging capabilities.

- Compliance & Certification: Ensure the chamber meets relevant international standards (ASTM, IEC, MIL-STD, FDA, etc.).

- Maintenance & Support: Factor in service availability, calibration, and spare part access for long-term reliability.

- Budget & ROI: Balance initial costs with long-term benefits, including energy efficiency, throughput, and test flexibility.

Unsure which chamber suits your needs? Search: How do I choose the best environmental chamber for my application and budget?

Choosing the Right Environmental Chamber Supplier

For the most positive outcome when purchasing an environmental chamber from an environmental chamber supplier, it is important to compare several companies using our directory of environmental chamber suppliers. Each environmental chamber supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each environmental chamber business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple environmental chamber businesses with the same form.

To make an informed purchase, consider these supplier selection factors:

- Reputation and customer reviews in the environmental testing equipment industry

- Range of standard and custom chamber models available

- After-sales support, calibration, and maintenance services

- Lead time, delivery, and installation support

- Availability of technical consultation and application engineering

- Warranty and service agreements

Want to compare top environmental chamber manufacturers? Try: Who are the best environmental chamber suppliers for my industry and location?

Frequently Asked Questions About Environmental Chambers

What is the difference between a temperature chamber and a climatic chamber?

A temperature chamber controls only temperature, while a climatic chamber manages both temperature and humidity. Climatic chambers are suitable for more complex simulations involving multiple environmental factors.

How do I ensure my environmental chamber meets regulatory standards?

Work with reputable manufacturers who provide chambers with documented compliance to industry standards (ASTM, IEC, MIL-STD, FDA, etc.). Request certification, calibration, and validation services to ensure audit readiness.

Can environmental chambers be customized for unique testing needs?

Yes, leading manufacturers offer custom-built chambers tailored for specific test conditions, sample sizes, integration with test equipment, and unique applications.

What are typical maintenance requirements for environmental chambers?

Regular maintenance includes calibration, sensor checks, refrigeration servicing, humidity system cleaning, and software updates. Planned maintenance ensures test accuracy and prolongs chamber lifespan.

How do I get a quote or more information about environmental test chambers?

Use our RFQ form to request pricing, technical specifications, and lead times from multiple environmental chamber suppliers. Our supplier directory and preview tool make it easy to compare options and connect with industry leaders.

Ready to take the next step? Contact us for expert guidance, quotes, and support in sourcing the right environmental chamber for your application.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services