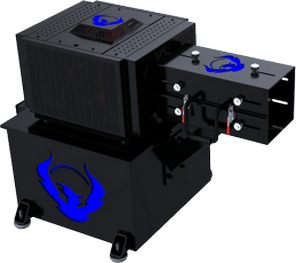

An environmental chamber or climatic chamber is an enclosed area that is used to test the effects of particular environmental conditions on industrial products, machine components, electronics, and biological items. These climatic chambers are designed to artificially control certain conditions such as heat and humidity. Any environmental condition can be created artificially, such as an extremely hot, cold, or even corrosive environment. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

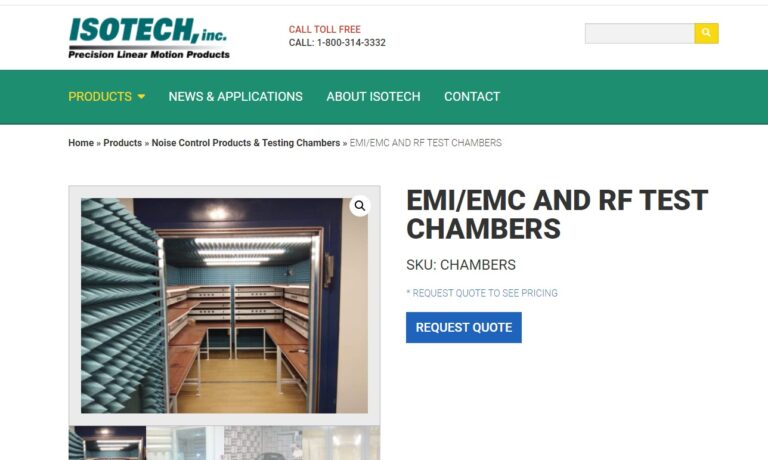

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Environmental Chambers Manufacturers

The conditions may include:

- Extreme temperatures

- Thermal shock

- Altitude

- Moisture or relative humidity

- Corrosion testing

- Salt spray

- Rain

- Weathering

- Vacuum

The manufactured specimen is introduced into the chamber, and different conditions are applied according to requirements. The sizes of test chambers can vary from 1 cubic foot (30cm) to 12,000 cubic feet (3,600 m).

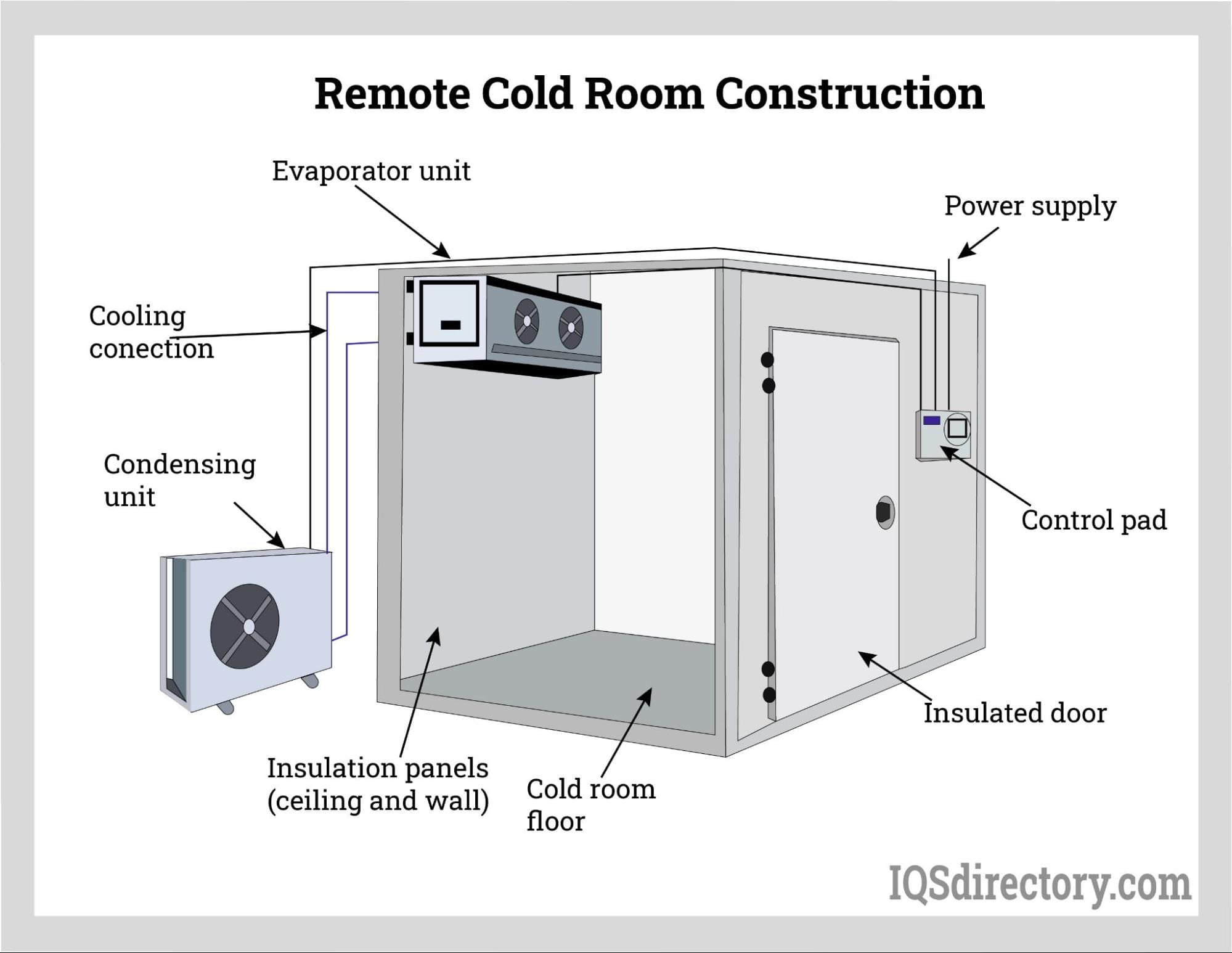

Working Principle of Climatic Chambers

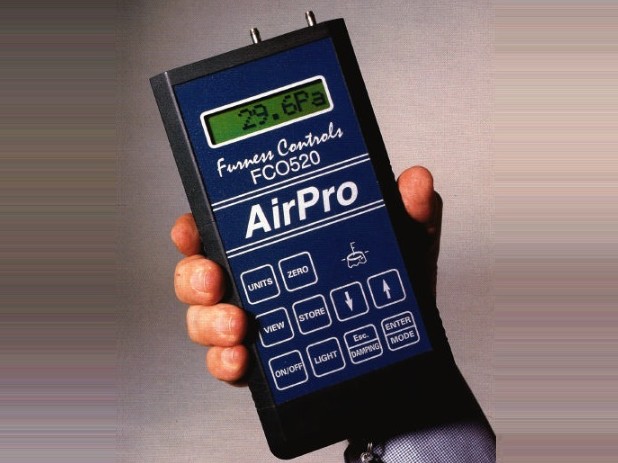

- All conditions of the chambers are controlled manually through a wide range of mechanical processes.

- The temperature is controlled by electric resistors either cooling or heating up the refrigeration unit.

- Water vapors are introduced into the chambers by steam generators.

- The humidity level is adjusted by one of two methods, ultrasound technology or water evaporation with a heat source.

- Corrosive conditions are simulated by emitting salt spray on the product.

- Not every test chamber can simulate each and every type of condition.

- For testing a product in a specific condition, specified test chambers are engineered.

Types of Environmental Chambers

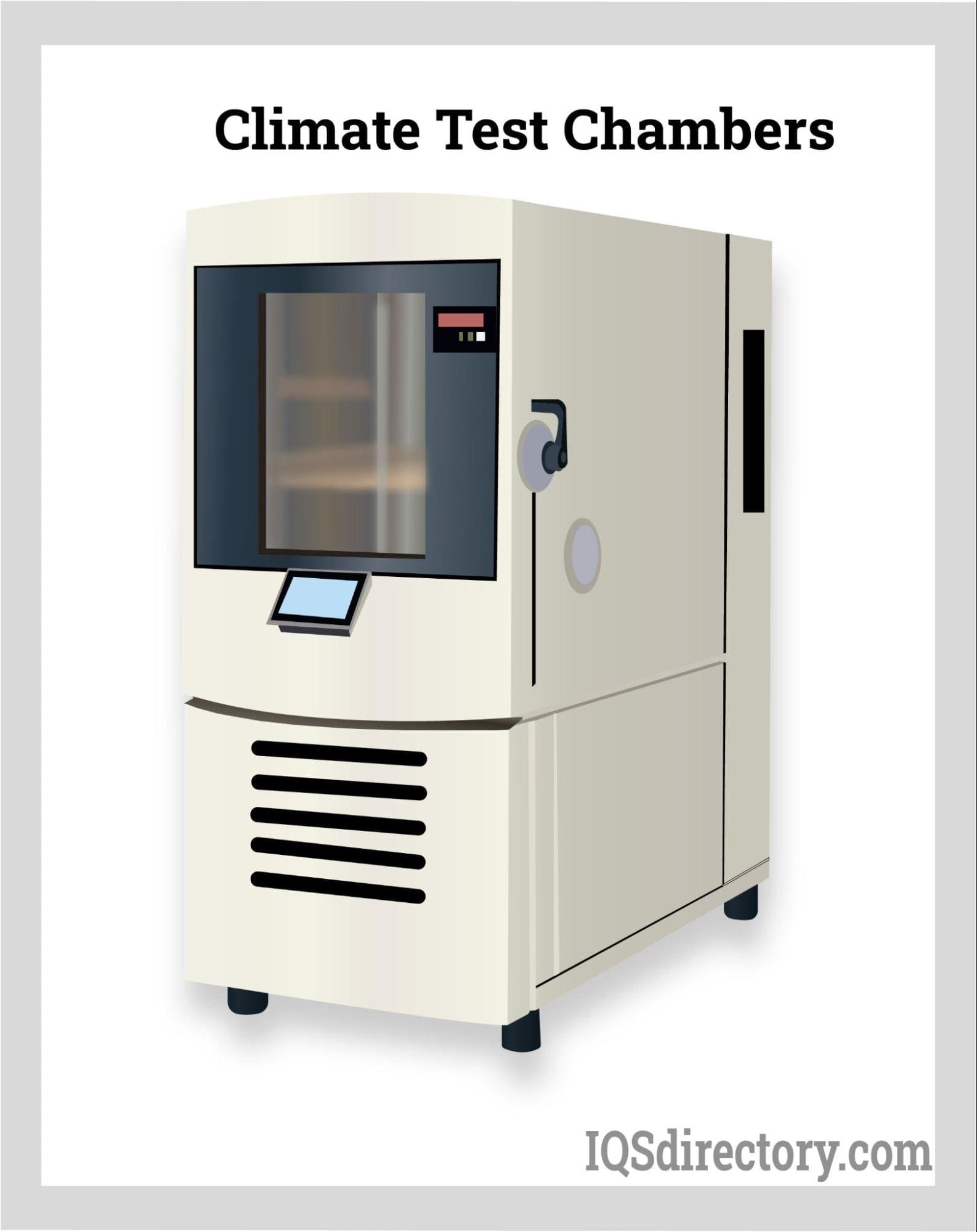

Temperature Chambers

- The temperature test is the most important test for a product. It may continue for days or weeks with the same gradient.

- These tests are called thermostatic tests and are used to determine the resilience of a product against temperature extremes.

- The temperature can vary from -94°F (-70oC) to 356°F (180oC).

Humidity Chambers

- The humidity test is the second most important test of a product.

- Humidity and temperature test chambers are linked with each other, as heat is required to produce humid conditions.

- The testing of a product can be done either in a static state without changing the conditions or in a dynamic or moving state.

Vibration Chambers

- Vibration testing is done by using mechanical and electrodynamic shaking.

- The shaking can be horizontal, vertical, or along three different axes.

- A product is tested under a highly accelerated life test and highly accelerated screen test to check its liability.

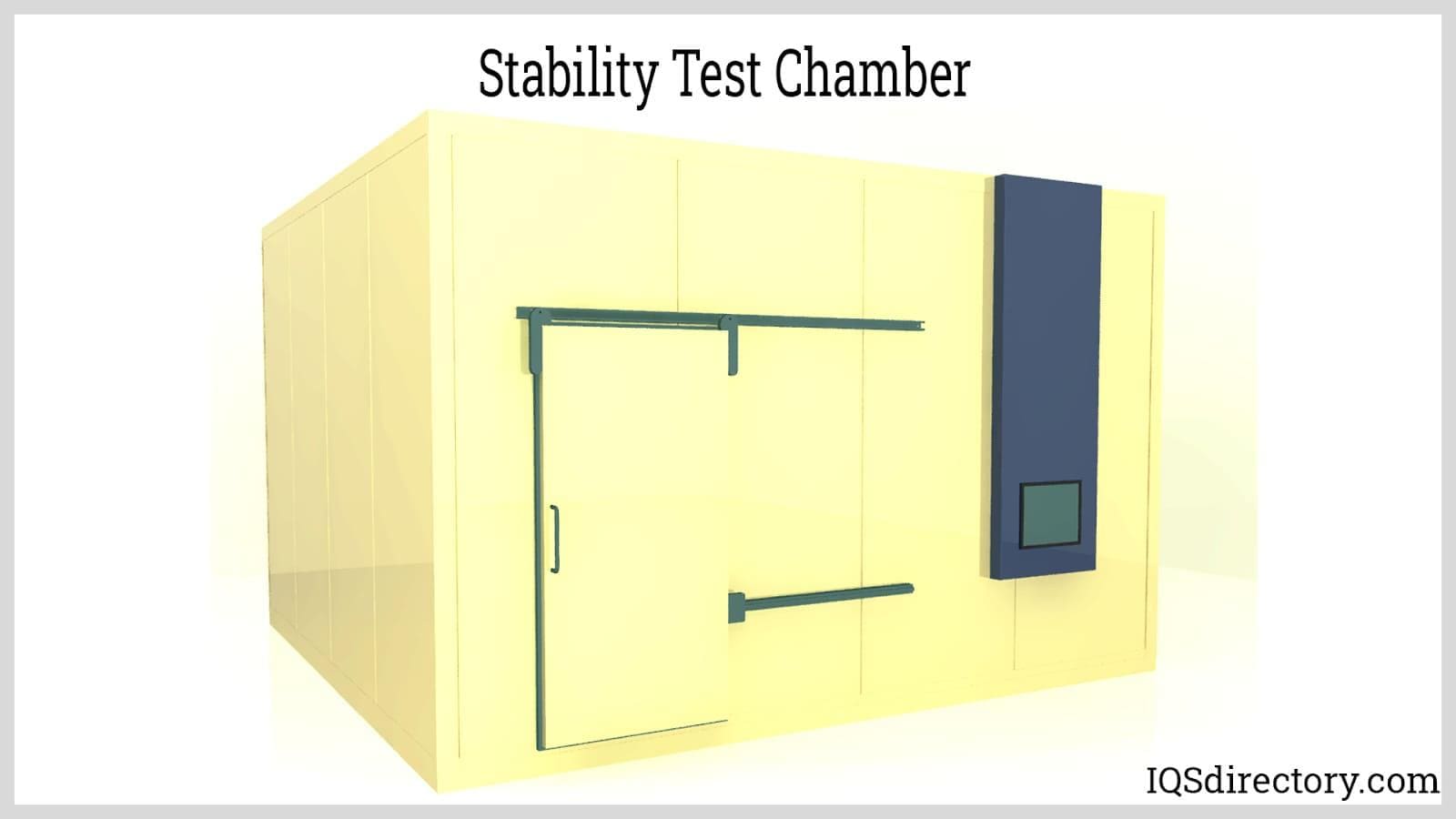

Stability Chambers

- Stability chambers are used to test the shelf-life of the product for shipping and storage.

- It is done by creating controlled conditions of temperature and humidity over an extended period of time.

Corrosion Test Chambers

- These test chambers are used to determine the ability of a product to withstand a corrosive environment.

- A salt spray is applied to the product surface with the help of a nozzle in the chamber.

- This test chamber determines the quality of the coatings and finishings of the product.

Thermal Shock Chambers

- Thermal shock chambers are used to check the ability of the product to withstand sudden changes in environmental conditions, such as temperature and humidity.

- The specimen is put under rapid and successive changes of temperature of 86°F (30oC) every minute or more.

Vacuum Chambers

- Vacuum chambers are used to test the products that are used in the aerospace and defense industries.

- This test is performed by creating an extremely low air pressure and removing all other gasses from the enclosed chamber.

- These tests are performed to check the working of the product in a vacuum.

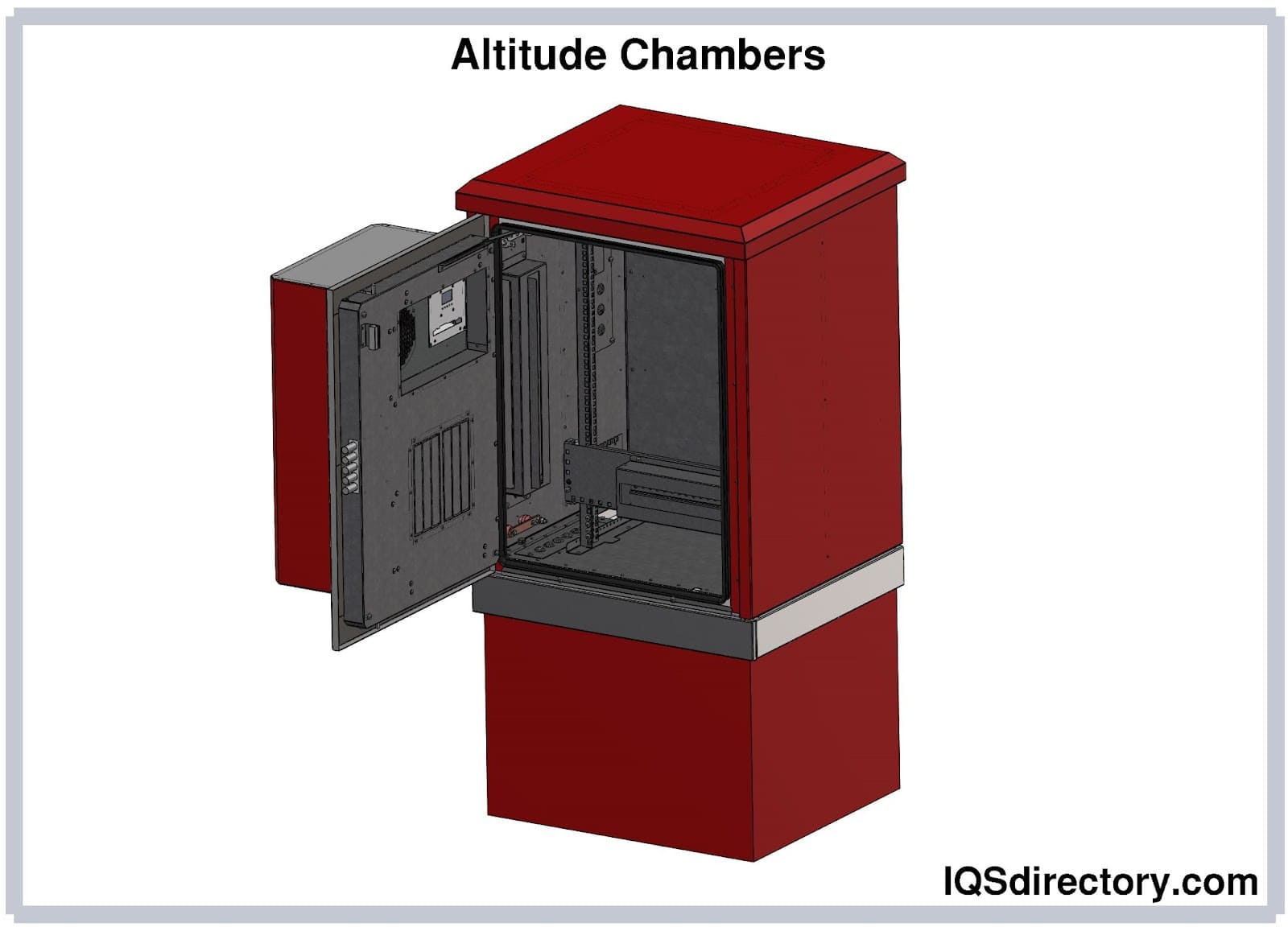

Altitude Chambers

- Altitude chambers are used to test the product’s resilience under low pressure at high altitudes.

- These chambers can simulate an altitude of up to 98,000 ft (30,000 m).

- Decompression and explosive testing are also a part of this testing chamber.

Anechoic Chambers

- Anechoic testing is done to check how much noise a product is producing.

- This testing chamber is the size of a room with walls covered in materials to block any incoming sound.

- The anechoic chambers work with the elimination of echos and all other sounds.

Industries Using Environmental Chambers

Automotive Industries

Small environmental chambers are used to check the reliability of the automotive parts before assembly.

Electronics Industries

Electronics parts such as circuits, boards, and switches are checked in these chambers before launching in the market. This is because they can be damaged by many environmental factors such as humidity, temperature or corrosive environments.

Pharmaceutical Industries

Pharmaceutical industries use these chambers to verify the lifespan and shelf-life of medicine.

Medical Facilities

Medical devices are monitored under these chambers before use.

Defense Industry

Military equipment is tested in these chambers to check if it can withstand harsh environments.

Telecommunications Industries

Telecommunication industries use these chambers to check their products in regard to altitudes.

Solar Power Plants

Solar panels are tested in environmental chambers to check if they can withstand a fluctuating environment or not.

Aerospace Industry

The aerospace industry uses vacuum test chambers to check the working of their products in space.

Types of Environmental Chambers

There are three types of environmental chambers according to their size. These are:

Bench-Top Chambers

Bench-top chambers are usually 0.5 cubic feet (15 cm) to 5.5 cubic feet (1.68 m). These are the smallest in size, and are used for commercial and industrial tests where a low temperature is required.

Reach-In Chambers

These are of size between 4 and 70 cubic feet (1.2 and 21.3 m). These can test for temperature, altitude, humidity, rain, solar and vibration.

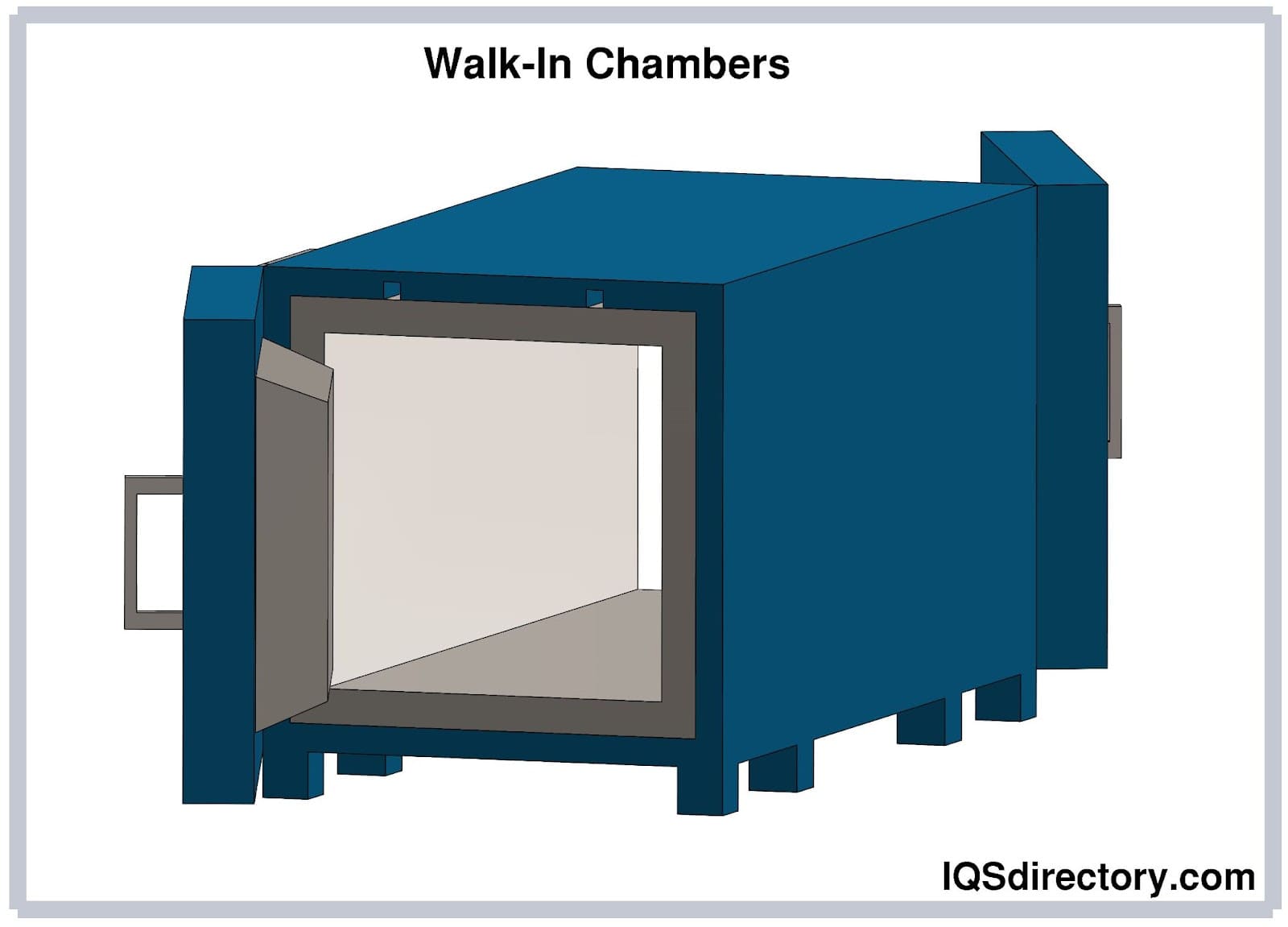

Walk-In Chambers

These chambers are big enough to walk or even drive into. These are used to test large components, from computers to satellites.

Choosing the Right Environmental Chamber Supplier

For the most positive outcome when purchasing an environmental chamber from an environmental chamber supplier, it is important to compare several companies using our directory of environmental chamber suppliers. Each environmental chamber supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each environmental chamber business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple environmental chamber businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services